Additive Manufacturing Market to Reach USD 133.51 Billion by 2032 | Size, Share, Trends & Forecast

Additive Manufacturing Market is growing fast as industries adopt 3D printing for faster prototyping, customization, and cost-efficient production.

Maximize Market Research highlights explosive growth in Additive Manufacturing Market at 21.86% CAGR, reshaping aerospace, automotive, and healthcare innovation.”

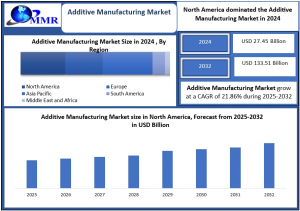

WILMINGTON, DE, UNITED STATES, November 19, 2025 /EINPresswire.com/ -- Global Additive Manufacturing Market size was valued at USD 27.45 Billion in 2024 and is projected to reach nearly USD 133.51 Billion by 2032, growing at a robust CAGR of 21.86%.— Dharti Raut

Global Additive Manufacturing Market Overview: Rapid Prototyping, 3D Printing Innovations & Industrial Growth Trends

Global Additive Manufacturing Market Report 2025 provides an in-depth analysis of market trends, size, and forecasts through 2032. The industry is experiencing rapid growth driven by increasing demand for rapid prototyping, industrial 3D printing, and metal & polymer additive manufacturing. Adoption of AI-driven design tools, hybrid manufacturing, and automated post-processing is transforming the market landscape. Expansion across aerospace, automotive, and healthcare sectors, along with technological innovations in DMLS, SLA, FDM, and binder jetting, continues to shape the future of the global Additive Manufacturing Market. Digital AM workflows, biocompatible materials, and scalable industrial 3D printers are key factors fueling market growth worldwide.

Unlock Insights: Request a Free Sample of Our Latest Report Now @ https://www.maximizemarketresearch.com/request-sample/146140/

What’s Driving the Rise of the Global Additive Manufacturing Market? Explore How Rapid Prototyping and AI-Driven 3D Printing Are Shaping 2032

Additive Manufacturing Market is growing fast as industries adopt advanced metal and polymer 3D printing, AI-powered design tools, and hybrid manufacturing technologies to accelerate prototyping, enhance precision, and scale production across aerospace, automotive, and healthcare sectors.

Global Additive Manufacturing Market Drivers: Rapid Prototyping & 3D Printing Transforming Healthcare, Automotive & Aerospace

Global Additive Manufacturing Market growth is being propelled by surging demand for rapid prototyping across healthcare, automotive, and aerospace sectors, leveraging advanced metal and polymer additive manufacturing, DMLS, SLA, FDM, and binder jetting technologies. Cutting-edge digital AM workflows, biocompatible materials, and industrial 3D printers are accelerating precision engineering, cost-efficiency, and scalable production, creating transformative opportunities for innovators and manufacturers worldwide.

Global Additive Manufacturing Market Challenges: High Costs, Skilled Labor Gaps & Adoption Barriers in Metal & Polymer 3D Printing

Global Additive Manufacturing Market faces key challenges from high initial investment costs for DMLS, SLS, and EBM systems, along with elevated operational expenses for AM software, certified materials, and ASTM/ISO compliance. Smaller enterprises (SMEs) encounter barriers related to short-term ROI, skilled labor shortages, and infrastructure requirements, limiting adoption despite the long-term potential of metal and polymer 3D printing.

Global Additive Manufacturing Market Opportunities: AI-Driven 3D Printing, Hybrid Manufacturing & Explosive Growth to USD 133.51 Billion by 2032

Global Additive Manufacturing Market is poised for explosive growth, with declining metal and polymer 3D printing system costs and innovative leasing models expanding access for SMEs. Rapid adoption in automotive additive manufacturing, aerospace AM, and healthcare 3D printing, combined with AI-driven design tools, hybrid manufacturing, and automated post-processing technologies, positions the market to achieve USD 133.51 Billion by 2032, unlocking unprecedented industrial opportunities in the 3D printing and additive manufacturing industry.

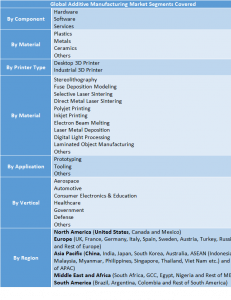

Additive Manufacturing Market Segmentation: Hardware & 3D Printers Driving Aerospace, Automotive & Healthcare Growth

Global Additive Manufacturing Market is strategically segmented by component, material, printer type, application, and industry vertical, with hardware dominating market share due to widespread adoption of industrial 3D printers in aerospace, automotive, and healthcare. Advanced metal and polymer AM systems such as DMLS, SLS, SLA, FDM, and binder jetting are driving rapid prototyping, tooling, and certified end-use production, unlocking transformative 3D printing trends, high-growth opportunities, and industrial innovation worldwide.

Feel free to request a complimentary sample copy or view a summary of the report @ https://www.maximizemarketresearch.com/request-sample/146140/

Automotive Additive Manufacturing Trends: AI-Driven 3D Printing, Metal AM & Mass Customization Driving Global 3D Printing Market Growth

Leading automakers like BMW and Volkswagen are scaling metal AM, FDM, and binder jetting to produce over 50,000 3D-printed components annually, driving lightweighting, topology optimization, and fuel efficiency. This trend highlights how automotive additive manufacturing is revolutionizing production cycles and redefining vehicle performance.

Automotive OEMs are leveraging AI-powered design simulation, AM software, and hybrid hardware-software solutions to enable mass customization of interior components, molds, and structural parts. Coupled with declining material costs and scalable production, this automotive additive manufacturing trend positions the sector as a high-growth driver in the global 3D printing market.

Additive Manufacturing Market: 3D Systems Innovations & GE Additive Rebrand Driving Global 3D Printing Growth

3D Systems has unveiled cutting-edge PSLA 270 polymer 3D printing platforms, advanced post-processing systems (Wash 400/Wash 400F, Cure 400), and high-performance SLS and MultiJet Printing (MJP) materials such as DuraForm PA12 Black and VisiJet Armor Max. These innovations are accelerating industrial additive manufacturing, high-resolution prototyping, and end-use part production, reinforcing the global additive manufacturing market growth and driving next-generation 3D printing solutions worldwide.

GE Additive’s strategic rebranding as Colibrium Additive marks a major transformation in metal 3D printing and industrial AM solutions. Retiring legacy brands and launching the “A New Future” campaign, the company emphasizes scalable, collaborative, and reliable additive manufacturing technologies, solidifying its position as a trusted leader in the global 3D printing, metal AM, and industrial additive manufacturing market.

Global Additive Manufacturing Market Competitive Landscape:

Global Additive Manufacturing Market is fiercely competitive, driven by rapid technological innovation, strategic partnerships, and consolidation among leaders like 3D Systems, Stratasys, GE Additive, HP, EOS GmbH, and Materialise. Emerging innovators such as Desktop Metal, Markforged, and Carbon leverage binder jetting, composite 3D printing, and AI-driven AM software, transforming the industrial 3D printing and metal AM market.

Vertical integration and end-to-end solutions define the Additive Manufacturing industry’s competitive landscape, as firms expand across hardware, software, services, and AM materials. Mergers, acquisitions, and cross-sector partnerships in aerospace, automotive, and healthcare enable mass customization, lightweight production, and high-performance 3D printing innovations, fueling global additive manufacturing market growth.

Global Additive Manufacturing Market: North America Leads, Europe Follows as 3D Printing Innovation Surges

North America dominates the Global Additive Manufacturing Market, fueled by early technology adoption, advanced industrial infrastructure, and world-class R&D capabilities. Leading companies like 3D Systems, Stratasys, GE Additive, and HP are driving metal AM, polymer AM, and industrial 3D printing innovations, reinforced by Industry 4.0 integration, digital manufacturing, and government-backed initiatives, accelerating regional 3D printing market growth.

Europe ranks as the second-largest region in the Global Additive Manufacturing Market, supported by advanced industrial and aerospace sectors, cutting-edge metal and polymer AM innovations, and strong R&D ecosystems. Strategic Industry 4.0 initiatives, government-supported digital manufacturing programs, and high-value applications are driving mass adoption of 3D printing, industrial additive manufacturing solutions, and regional market expansion.

Additive Manufacturing Key Players:

1. 3D Systems, Inc.

2. Stratasys Ltd.

3. GE Additive

4. EOS GmbH

5. HP Inc.

6. Materialise NV

7. SLM Solutions Group AG

8. ExOne Company

9. Desktop Metal, Inc.

10.Renishaw plc

11.Markforged, Inc.

12.Voxeljet AG

13.EnvisionTEC GmbH

14.Proto Labs, Inc.

15.Arcam AB

16.Carbon, Inc.

17.Xometry, Inc.

18.Ultimaker B.V.

19.Formlabs, Inc.

20.Nano Dimension Ltd.

21.Optomec, Inc.

22.Additive Industries B.V.

23.TRUMPF GmbH + Co. KG

24.HP Metal Jet

25.Siemens AG

26.BASF 3D Printing Solutions GmbH

27.Autodesk, Inc.

28.XYZprinting, Inc.

29.BigRep GmbH

30.GKN Additive

Strategic Growth Drivers and Technological Advancements Shaping the Global Additive Manufacturing Market | Forecast 2025–2032

♦ 2019–2024 Technological Momentum: Leading industrial 3D printer manufacturers such as 3D Systems, Stratasys, and GE Additive introduced advanced metal and polymer AM systems, accelerating high-precision prototyping, tooling, and end-use part production.

♦ Rising Industrial Adoption: Aerospace, automotive, and healthcare sectors are increasingly leveraging FDM, SLA, DMLS, binder jetting, and hybrid AM technologies to enhance lightweighting, performance, and manufacturing efficiency.

♦ AI & Digital Integration: The integration of AI-driven design tools, AM software, and digital workflows is reducing product development cycles and enabling mass customization.

♦ Material Innovation: Advancements in high-strength metals, biocompatible polymers, and multi-material 3D printing are expanding functional and certified end-use applications.

FAQs:

What is the projected size of the Global Additive Manufacturing Market?

Ans: Global Additive Manufacturing Market was valued at USD 27.45 Billion in 2024 and is expected to reach nearly USD 133.51 Billion by 2032, growing at a CAGR of 21.86%.

What are the key drivers of growth in the Additive Manufacturing Market?

Ans: Growth is fueled by rapid prototyping demand, adoption of metal and polymer 3D printing, digital AM workflows, AI-driven design, and industrial applications in healthcare, automotive, and aerospace.

Who are the leading companies in the Additive Manufacturing Market?

Ans: Top players include 3D Systems, Stratasys, GE Additive, EOS GmbH, HP, Materialise, Desktop Metal, Markforged, and Carbon, driving innovations across metal AM, polymer AM, and industrial 3D printing solutions.

Analyst Perspective:

Industry observers note that the Additive Manufacturing sector is undergoing significant transformation, driven by expanding adoption of metal and polymer 3D printing in healthcare, automotive, and aerospace. Leading companies such as 3D Systems, Stratasys, and GE Additive continue to innovate, while emerging players utilize AI-driven AM software to gain traction. Experts highlight the sector’s strong potential for operational efficiency, mass customization, and scalable production, attracting strategic investments and partnerships across the industry.

Related Reports:

Manufacturing Operations Management (MOM) Software Market: https://www.maximizemarketresearch.com/market-report/global-manufacturing-operations-management-mom-software-market/81502/

Manufacturing Analytics Market: https://www.maximizemarketresearch.com/market-report/manufacturing-analytics-market/52701/

Maximize Market Research launches a subscription platform for continuous access to global market insights and analysis @ https://www.mmrstatistics.com/

About Us

Maximize Market Research is one of the fastest-growing market research and business consulting firms serving clients globally. Our revenue impact and focused growth-driven research initiatives make us a proud partner of majority of the Fortune 500 companies. We have a diversified portfolio and serve a variety of industries such as IT & telecom, chemical, food & beverage, aerospace & defense, healthcare and others.

MAXIMIZE MARKET RESEARCH PVT. LTD.

2nd Floor, Navale IT park Phase 3,

Pune Banglore Highway, Narhe

Pune, Maharashtra 411041, India.

+91 9607365656

sales@maximizemarketresearch.com

Lumawant Godage

MAXIMIZE MARKET RESEARCH PVT. LTD.

+ +91 96073 65656

email us here

Visit us on social media:

LinkedIn

Instagram

Facebook

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.